Benefits of Partnering With SCS Elevator for Your Plastic Injection Molding Needs

For more than 40 years, SCS Elevator Products has been a highly respected quality supplier of a variety of products — most notably elevator signage, buttons, and jamb and cab braille.

But did you know that, in addition to the products we sell, we also offer manufacturing services, including plastic injection molding and mold design?

With the instability brought about by recent supply chain disruptions, many companies who currently rely on overseas manufacturing have begun searching for an alternative manufacturer in the U.S.

If that’s you, SCS Elevator could be the right fit.

Manufacturing Overseas Has Fewer Advantages Than It Used To

Over the past 40 years, manufacturing of everything from clothes to medicine to electronics has moved overseas. The primary goal was to reduce costs: cheaper manufacturing meant lower costs not only for the manufacturer but also for the end user.

But the supply chain disruptions of the past two years have revealed just how vulnerable the current system is. Disruptions due to the COVID-19 pandemic have led to continual delays and shortages, begging the question, “Is overseas manufacturing really cost effective anymore?”

As a result, we’re beginning to see a push to bring manufacturing back to the U.S.

From small businesses to huge corporations, companies are rethinking the way we manufacture the products we use every day. Even corporate giants like General Motors, Toyota, and Samsung have recently announced plans to increase manufacturing in the U.S..

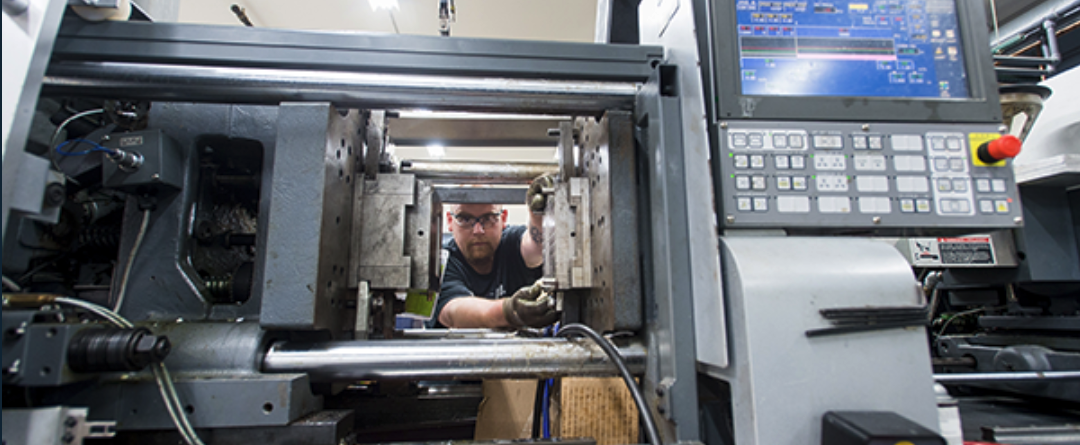

SCS Elevator Can Handle Your Plastic Injection Molding Needs Here at Home

With this shift, SCS Elevator is uniquely positioned to serve as an alternative to overseas manufacturing for companies looking for injection molded parts.

Our injection molding department features a wide range of press sizes to accommodate a variety of parts. Our expertise includes:

- Low- to high-volume runs

- In-mold decorating and applied cliche

- Pad printing

- Sonic welding

- 3D prototyping and printing

We also provide part design services. Whether it’s adapting an existing tool or designing a new tool from concept, we have the expertise needed to meet — and exceed — your expectations.

Benefits of Partnering With SCS for Plastic Injection Molding

At SCS Elevator, we are agile enough to do small runs cost effectively, but we also have the experience and staff needed for large quantity runs. We can grow with you!

In addition, when SCS Elevator handles your injection molding needs, you’ll benefit from:

- U.S.-based manufacturer

- Established suppliers (meaning fewer supply chain issues)

- Thermoplastic injection molding 80-250 ton presses with lights-out capabilities

- Tool design, modification, maintenance, and warehousing

- In-mold decorating and applied cliche

- Design and engineering assistance

- Ancillary services, including 3D prototyping, painting, assembly, packaging, shipping, and more

- Top-notch service from a passionate, talented, and dedicated team

If your company has molds nearing the end of their lifespan or is in need of molds for new products, consider partnering with SCS Elevator to meet your needs right here in the U.S. instead of looking overseas.

Ready to reap the benefits of entrusting your injection molding to SCS? Contact us for your next project!

SCS Elevator is the leading manufacturer of elevator jamb braille, cab braille, and elevator signage in North America, as well as a provider of high quality domestic manufacturing services. Whether you need specialized order fulfillment or custom products, SCS is here to help — contact us today!